How is a Zipponi faucet born ?

#HowWeMadeIt

Zipponi it’s a member of a big company: WTS SpA.

WTS stands for the excellence of sanitary taps. The industrial group represents the best brands in the sector, projected to the international market.

WTS means: reliability, practice, cutting edge design, and attention to the surrounding environment.

There are several stages in the entire production process of a refined design, in its functional and eco-sustainable structure.

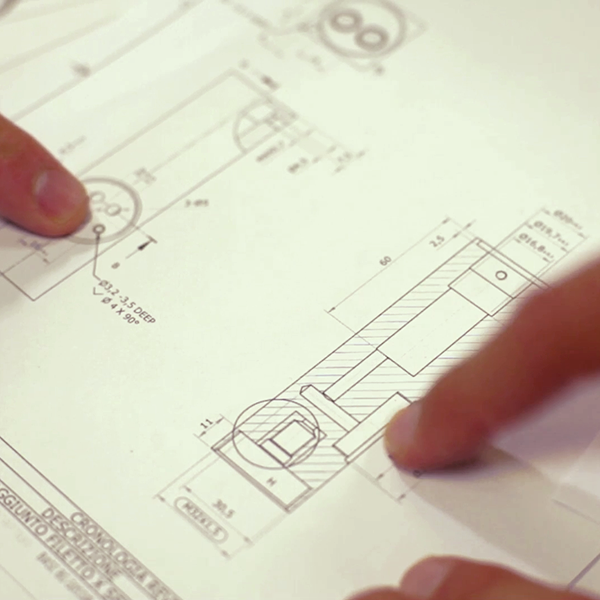

R&D

//

Each Zipponi tap is produced by intelligence and experience of WTS Group and every step of the production cycle is excellent expression of quality. After the approval of the concept design, in the planning phase, tap is engineered by the technical office of WTS: for that purpose, it’s required the use of sophisticated 3D design software. Then we move to the next step, the prototyping …

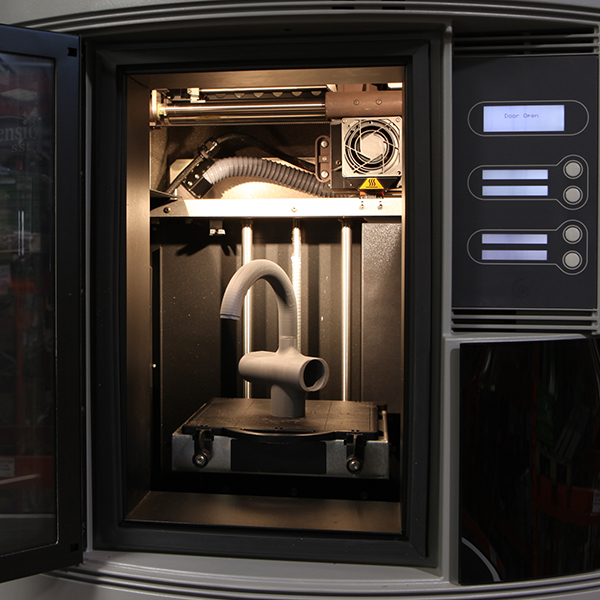

Prototyping

//

Now it’s time for the second phase of Zipponi tap’s production, thanks to the excellent and innovative work of WTS Group.

Today we talk about prototyping, the passage that allows to create the prototype of the new tap: for this, you need a 3D printer, defining the shape from the analysis of the real 3D model in ABS plastic.

Sand-core production

//

Our approach to learning about how born a Zipponi faucet continues with the third phase, the sand-core preparation, always under the excellent work of WTS Group. It’s an mixed element of sand and special synthetic resins and it’s designed in a special mold, the sand core box. The sand-core is extracted once hardened: the element obtained is used to create the internal cavity of the faucet body, when it’s inserted into the mold for the fusion, called the “shell”.

Foundry

//

During the foundry phase, the special mold, said shell, is filled with a molten brass cast, a copper and zinc alloy, the raw material used to blend the faucet body. From the shell (in which, before to casting, the previously described soul is inserted) the shape of the desired body is then extracted.

Machining

//

We talk about machining, leading products, obtained from previous merger, to be processed with automatic lathes, allowing, thus, to create the mechanical shut-off devices, mixing and deviation, characteristic of the taps; the faucets, then, pass through the Transfer machines line, to be the subject of the various machining processing requested.

Polishing

//

The polishing cycle, allowing you to sand finely (using abrasive belts with different grain size and discs made of suitable fabrics) surfaces of machining products: these processes are executed with automatic robotized systems islands, allowing it to pass to the next treatments chromium plating.

Chrome Plating

//

Chrome plating is one of the basic steps of making a Zipponi tap : WTS’s dedicated and innovative work emphasizes that galvanic treatment is important both to protect and preserve the faucet as to make it a unique design element. Chromium consists of the deposition of double nickel and chromium coatings, through the diving of the pieces to be chromed into a series of baths of electrolytic solutions. The WTS ECO GREEN SYSTEM also stands out in the ecologically zero-emission chrome plating process.

Quality Control

//

The Quality control is careful and detailed assessment of taps making: it consists of a series of strict controls on the components, just out of the stage of production, performed both in dimensional level both in the aesthetic (for example, the chromium plating must not have imperfections). All this takes place by means of specific tools, which check its compliance with the initial technical drawings.

Assembly

//

From meticulous and strict Quality Control switches to new phase, Assembly, in which the necessary components are mounted inside the faucet body.

Homonymous department in charge, the various operations are performed by “islands” with the necessary equipment, to ensure a high level of product quality.